New technology equipment for laser additive and micro cutting hybrid manufacturing,

By combining the advantages of selective laser melting and ultrafast (such as picosecond and femtosecond) laser cutting technology, the surface accuracy of complex structural parts can reach the micrometer level, effectively reducing surface roughness and solving problems such as hole collapse angle;

Effectively applied in the manufacturing fields of precision molds, medical dental implants, precision inner cavity terminal parts, and microstructure parts.

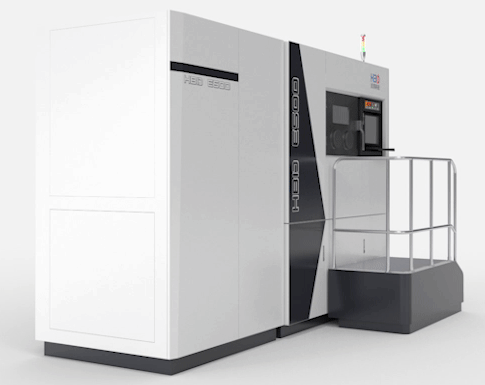

Enhanced large-size, efficient and high-quality printing equipment, complete powder management, safe and long-lasting filtration system, mature and excellent wind farm design, stable and intelligent multi path design and control, to meet the needs of higher size, high intensity, and continuous production,

Focusing on aerospace, automotive component manufacturing, and other fields.

Materials used: titanium alloy, aluminum alloy, high-temperature alloy, stainless steel, mold steel.